Virtual Taste Testing: How AR and VR Are Redefining Food Development

From digital kitchens to sensory simulations — chefs are now designing flavors in the metaverse before ever touching an ingredient.

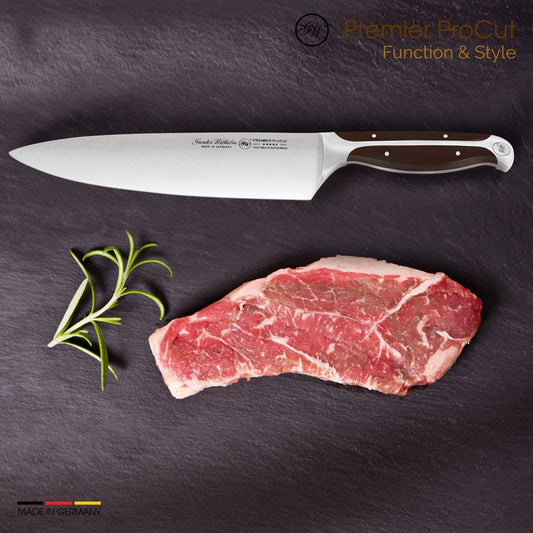

In the not-so-distant past, chefs perfected dishes by taste, smell, and intuition — hours of trial and error in the kitchen. Today, they can do it without ever picking up a knife. Thanks to the rise of augmented and virtual reality in food innovation, entire recipes are being developed, tested, and tweaked in the digital realm — before a single gram of flour or drop of oil is used.

It’s part of a larger movement toward “virtual gastronomy” — a blend of technology, data, and imagination that’s reshaping how the world’s top kitchens invent the future of flavor.

👩🍳 Designing Taste in the Digital World

Virtual taste testing uses AI-powered sensory modeling to simulate how ingredients interact — predicting texture, aroma, and flavor balance through chemical data and haptic feedback. Chefs wearing VR headsets can now “taste” a digital prototype, experiencing flavor intensity or even mouthfeel through sensory cues.

“It’s like Photoshop for food,” laughs chef-innovator Marco Del Sol. “You can test a dozen variations of a sauce without wasting ingredients — just tweak the digital salt or the acidity and instantly feel the difference on your tongue.”

🌐 The AR Kitchen Revolution

Augmented reality brings a similar transformation to the physical kitchen. Through AR overlays projected onto countertops or smart glasses, chefs can see ingredient pairings, plating suggestions, or live nutrition breakdowns in real time.

For example, an AR headset might guide a cook through a recipe, showing how flavors will combine — or warning if an ingredient disrupts balance. Some fine dining labs are even experimenting with AI-guided plating in 3D space, using projection mapping to visualize presentation before serving.

🧠 Flavor Engineering & the Science of Imagination

Behind these futuristic tools lies a powerful new discipline: flavor engineering. Using AI algorithms trained on molecular data and global recipe databases, systems can now generate flavor combinations that humans might never think of — say, roasted pineapple with miso caramel, or saffron with aged cocoa.

The result? Chefs become curators of experience, not just ingredients. They can explore entire menus in virtual form — adjusting sweetness, acidity, or umami levels with digital precision before committing to a single ingredient order.

🧂 Sustainability Meets Simulation

Beyond creativity, virtual food development is also a sustainability win. Every dish refined in VR means fewer wasted ingredients, less energy used, and a dramatically lower carbon footprint. Large restaurant groups and food tech companies are already using virtual testing labs to cut R&D costs while maintaining culinary innovation.

“In the past, testing ten versions of a product meant hundreds of kilos of waste,” explains Dr. Aiko Murata, lead researcher at NeuroTaste Labs. “Now, we can digitally model taste evolution and bring only the final recipe to the real kitchen.”

🌈 The Future of Dining: Blending Real and Virtual

The ultimate vision? Restaurants where virtual and physical experiences merge. Imagine tasting a dessert enhanced by an AR overlay — the sweetness subtly shifting as the colors on your plate change. Or interactive tasting menus where diners design their own dishes in VR before they’re brought to life by the kitchen.

Food is becoming a multisensory experience — part flavor, part technology, all imagination. In this brave new world, chefs are not only artisans but digital architects of taste.

The next great flavor may not be found in a kitchen at all — but coded in the cloud, waiting to be tasted.

Share: